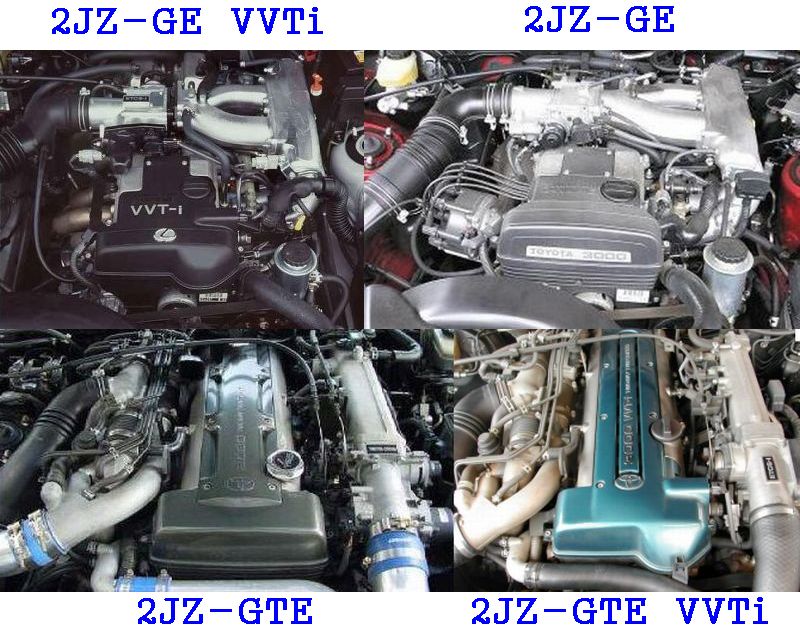

The focus of this article will be the timing belt replacement on a 2001 GS 300 with the i n-line six-cylinder 2JZ-GE engine with VVT-i (Toyota’s variable valve timing). Nothing can spoil the resale value of a high-dollar car more than an engine failure. Align the matchmarks of the timing belt and camshaft timing pulleys Remove any oil or water on the camshaft timing pulley, and keep it clean. Install the timing belt, checking the tension between the crankshaft timing pulley and exhaust camshaft timing pulley. Set timing belt tensioner. 1JZ-GTE VVTi; 2JZ-GE; 2JZ-GTE; 2JZ-GTE VVTi; 3S-GE BEAMS. 3S-GE BEAMS Altezza SXE10 (1998-05). COVER, TIMING BELT, NO.3 $ 160.00. Timing Belt Tensioner PS Pump Pulley Lower Radiator Hose Timing Belt Guide Timing Belt Plate x 5 Radiator Assembly Reservoir Inlet Hose No.2 Fan Shroud x 16 Engine Under Cover Hose Clamp Oil Cooler Tube A/T x 10 Fan and Fluid Coupling Assembly precoated part Non - reusable part EM-14 ENGINE MECHANICAL (2JZ-GTE) - TIMING BELT Author: Date: 1119.

THE 1JZ/2JZ GTE VVTi SYSTEM

In the 8+ years I've been working on VVTi engines, some of my customers and I have heard just about every excuse as to why VVTi would not work with high HP applications. I got responses like, 'good luck!'... ... ' what shop is doing it?'... ... 'No one will tune it'... ... 'you need expensive engine management to tune it'... ... 'It will choke power in the top end'... ... ' No race team is using it'... ... 'wiring is difficult'... ... 'no aftermarket support because it doesn't make power.' Blah blah blah, blah-blah!!! Yes, I have heard it all!. So, just in case you are reading this, and YOU are one of those who have said these things, or you are one of those other shops doing R&D (Research & Duplication) sit back and learn a few things!

What is VVTi? VVT-i, or Variable Valve Timing with intelligence, is an automobile variable valve timing technology developed by Toyota.VVT-i, introduced in 1996. It varies the timing of the intakevalves by adjusting the relationship between the camshaft drive (belt, scissor-gear or chain) and intake camshaft. Engine oil pressure is applied to an actuator to adjust the camshaft position. Adjustments in the overlap time between the exhaust valve closing and intake valve opening result in improved engine efficiency.

Easy right? Wikipedia is your friend! LOL Need to see it in a video? Look bellow! Thanks to Jonathan J. Gautier for the link.

The VVT gear This is an area of concern for those that are not informed. Can it go bad? Yes it can. IF you unplug the VVT solenoid and plug it back in while the car is running, yes it can go bad. It will strip the gears inside! The other problem is that it leaks. Most likely its already 15+ years old!. These are easy fixes, buy a new one if you are not sure of it's health. (Come on! If this was a non VVTi engine you would have spent money for a HKS or Titan gear anyways!)

Other parts that you want to check for optimum VVT reliability is the oil control filter. this one is located in the the upper banjo bolt of the VVT oil feed line. (Thanks Toyota for placing it there)

The VVT solenoid This little thing controls oil to the gear to advance and retard the cam timing. This, paired with the factory ECU and cam and crank sensors, is what makes the magic happen. Change the factory ECU with one of our EMS packages, add some E85, bigger injectors and your choice of Turbochager (Comp turbo, BW, Garrett) on stock internals. We have had great results on 100% internally stock engines.

This dyno Graph is from a 100% internally stock block/head 2jzgte with a Comp turbo 67mm Turbo. The off boost drivability of this car is nice. This kind of response on the street is killer. It has plenty of torque where you need it, when you need it. It is all done with a factory R154! No fancy parts, just good old heavy shock proof!

The engine setup Well it looks like this...

2jz Non Vvti

We use coil on plug from the TT engine with the igniter. No DLI yet, until we start to eclipse 750+ whp. A better ignition system will gain more ponies but hey, the stock system works! The EMS we use for this car is our very own modded AEM EMS and our own harness. It controls AICV just like stock ecu, giving you great start ups everytime.

So far we have seen what the VVT system can do in stock longblocks, but what can it do for heavily modified cylinder heads and built blocks? Well the System doesn't know if it's on a stock engine or a fully built longblock. It doesn't.

The Test We had built a non VVT engine for a customer over 4 years ago. This block and head combo has made over 900 whp before. All supertech valve train, dual springs, beryllium copper seats, shimless buckets and GSCS2 cams. The block has Tomei pistons and Manley turbo tuff rods. ACL bearings and billet main caps finish off the block to create a bullet proof engine. Now, 4 years later, when we want to remove the head, and install a built VVTi head with the same components as the non VVTi head. Setting up the VVTi head with the same cam profile and duration was an easy task thanks to GSC power division. The port job was also done by the same machine shop and they had the flow numbers from the first one so it was easy to match. So to top things off, the leakdown of the old head bolted to the block was 3% across the board. Why is it important to check this? It tells us that the engine is healthy and that the head is performing at its best. Once the VVTi head was bolted down, we rechecked that the leak down was the same... and it was! We then started our back to back test. Using the same intake and turbo manifolds as the non VVTi engine, same Turbo, same gas in the tank and the same boost levels it was going to tell us once and for all what the difference was. The difference was jaw dropping!

The Difference between a VVTi (solid red line) and non VVTi (light red line) cylinder head shown above, on the same car, same block, same compression (8.5:1), same tank of e85, and same boost levels, with the same lift and duration on cams, shows the gains at 5000 rpm. Torque went up by 276 ft lbs and whp increase by 269 hp! Another aspect that increased was the MPG! It went from from 16 ish to 21 mpg on e85! Now the car didn't drive like the typical lag monster Supra Brent was used to.

The magic questions?... What does it do against a similar built stroker? What if the stroker had higher compression?

BAM! blue line is the stroker! We built both cars, we used the same dyno.

Do you think VVTi is worth it yet? What if it had a 10.5:1 compression block, stroker? Nitrous? quick spool valve? Maybe it will need to run a full MT ET street all the time! If torque wins races why not use VVTi? Is it hard to tune? No, the System is easy to setup depending on how much you want out of it and how aggressive you want to set it. At this point, is safe to say that we need more ignition. The TT coils and HKS DLI can't handle the overlap and blows out the spark.

The Non VVTi engine bay

The VVTi engine bay.

Here you can see the Air induction box that Leilani and I made. I know it doesn't have anything to do with the topic but I wanted to show it to you... Also the big ETS 6 inch Intercooler core, functional AC, as well. Just before we finished the air box, Speedhunters came by the shop to snap some pics of the Scrapyard Scamp (also VVTi powered) and wanted to feature Brent's car as well. http://www.speedhunters.com/2015/01/the-eternal-supra-refining-an-icon/

Brent was responsible for making this VVTi project happen. He is always willing to push the envelope of his car. Once we knew that the engine was healthy enough to take all the abuse we could throw at it, we knew that the only way it can go was up! AEM was also great help. Beau Brown of BBR tuning made this thing come true as well. His skills are second to none.

8+ years of messing with VVTi and these are some of the VVTi projects we have worked on.

2JZGTE powered by A comp turbo 6767 using a MS3pro EMS owned by Dave Buckshaw!

Rodel's undisputed, show stopping A70

NA-T VVTi :)

Soapra!

Kenny bells, whipples, AWD E85 Evo's and lots of dead snakes and horses! Julio's Supra now on E85 and over 600 whp!

Silent killer! Stock looking, wastegate recirculated 4 door Supra! 25 MPG to boot and stock ecu!

Went from Non VVTi to VVTi. Original shop sold a busted 2jz to this customer. We made it right. Also made a new harness and routed it in the right place. Using an AEM V1 for A 7MGTE!

Dsport Cover, project Soristo/SC300! on AEM Infinity 10

Auto, VVTi, Single turbo E85 on AEM V2!

AEM Infinity 10 tuned by BBR tuning, owned by Brent Huckaby. Comp turbo 7483 Turbine!

We didn't work on this one, but it's engine porn! VVTi as well so why not! 1200 HP Daigo Saito's Drift car

We have proved that VVTi is worth having in any application, from street to strip, road racer to drift car, this technology is amazing just as the bullet Proof JZ engines. Now that we have discombobulated the JZ engine tuning Mantra, will JZ VVTi find its self in your engine bay? Don't take my word for it, Nissan guys are using them as well!

Add a Comment

This is a guide to replacing a cam gear/s on the 2JZGTE or 2JZGE engine.

Some of these steps can be used to replace the timing belt, but not all, in the future I hope to have a full article on that process.

The process and pictures were taken mostly on my 2JZGTE VVTi supra, there are a few pictures of my old 2JZGE also – the process is almost identical and can be followed for both turbo and non-turbo engine models. The same process can be followed on the non-vvti, the VVTi has only the exhaust side cam gear that can be replaced, the non-vvti can have the exhaust and intake cam gear swapped out.

I have also done this with the engine out which makes it a lot easier to get parts off, I may only briefly touch on some steps that I didn’t have to do, also if you’re going to do this then I suggest you do your timing belt and water pump if need be, good time to change your coolant and flush/bleed system once done also, plus any seals or maintenance items.

Tools required; (*Optional)

- Torque wrench

- Socket set and extension bars (10, 12, 17, 22 mm sizes)

- Screw driver

- Pliers

- Jack and Stands (Safety First!)

- Coolant *

- Timing Belt *

- Water Pump *

- Cam seals *

Process;

- Diagram

- Disconnect the battery cables and clamp then remove the battery. Using a 10mm socket, remove the 3x 10mm bolts holding the battery tray in

- Jack up car and put it safely on stands, get you 10mm socket and undo engine under cover (this will aid in removing radiator, removing fan, removing, shroud, disconnecting any plugs like electric fans if you have them, getting to timing belt tensioner)

Diagram EM15 Part 1 –

- Get the pliers and remove the clamps on the radiator hoses (Do one end and drain into bucket, do a coolant change while your at it)

- Remove radiator, fan shroud (10mm bolts on radiator) and electric fans/plugs

Diagram EM15 Part 2 –

- Remove drive belt tensioner damper (2x 10mm bolts)

Diagram EM15 Part 3 –

- Remove drive belt (Put socket over dampener bolt and push down clockwise to loosen off), remove clutch fan (4x 10mm nuts) – Don’t worry about where it mentions in step 3 to look at removing water pump pulley)

- Remove timing belt cover (10mm allen heads) – Don’t worry about where it mentions in step 3 to look at removing water pump pulley, this is not required

Diagram EM15 Part 4 –

- Not required for removal

Diagram EM15 Part 5 –

- Remove the 5mm allen head bolts on the spark plug cover, remove spark plug cover (NA has 3x bolts, TT nas 12x bolts). Also remove any intake or piping/plumbing for easier access if required

Diagram Part 6 –

- Remove the 5mm allen head bolts on the lower spark plug cover

- You should now have something similar to this (TT top picture, NA bottom)

Diagram EM15 Part 7 –

- Not required

Diagram EM16 Part 8 –

- Follow instructions part 8a and 8bonly, making sure your timing is at TDC 0 (white line) also mark your timing belt with something to match up with the cam gear marks like a crayon that I used. You will see the marks on the cam gear will match up with the notches at the back too. If they don’t match up then turn the crank clockwise another 360 degrees until the cam gear notches line up and crank is at TDC 0.

- Unless you have an SST then do this, loosen your cam bolt(s) here while you still have tension on the timing belt (Use 22mm socket on the crank bolt to stop it moving while you loosen the cam gear bolts, they are tight)

Diagram EM16 Part 9 –

- 9 Only – Optional – There is no need to completely remove the timing belt

- 9a – By now you should have access to the drive belt tensioner so loosen these 2 (12mm) bolts (DON’T TAKE THEM OFF), this will take tension off the belt, it is the rusty looking thing.

- By now, you should have enough slack to easily remove the timing belt, if not loosen bolts a little more on the belt tensioner. BE VERY CAREFUL HERE!!! You don’t want to bump the cam gears or the crank pulley or you could seriously throw your timing off! Carefully back the cam gear bolt back out and set aside.

- Take the cam gear off carefully and put new cam gear(s) on, making sure the teeth or the belt don’t move, the cam gear is keyed and can only go on one way, your marks should line up, if not make sure they do! (If your not VVTi do the other side too, but make sure you do one side at a time)

Diagram EM23 Part 9b, 10a and 10b –

- From here you just need to put cam gear bolt back in and do up hand tight ensuring camshaft timing markings are correct

Diagram EM23 Part 11-

- Not required unless you removed timing belt tensioner

Diagram EM23 Part 12-

2jzge Vvti Turbo

- Tighten torque drive belt tensioner bolts back up evenly to 20ft/lbs with a torque wrench, also making sure your belt is on evenly (look from above).

- Next get 22mm wrench again and put on crank bolt and get torque wrench and do up cam gear bolt 59ft/lbs (using crank bolt to stop from moving)

- As far as timing and tuning goes please use instructions provided or get your mechanic/tuner to do for you, make sure you use loctite on cam gear bolts.

- Install everything back on and make sure TDC is at 0 and the cam gears line up with the marks, also make sure everything is put back together and you’re not missing screws and nuts that you put everywhere, also do a coolant flush/bleed system.

- Old cam gear out and new cam gear in – job complete!